We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

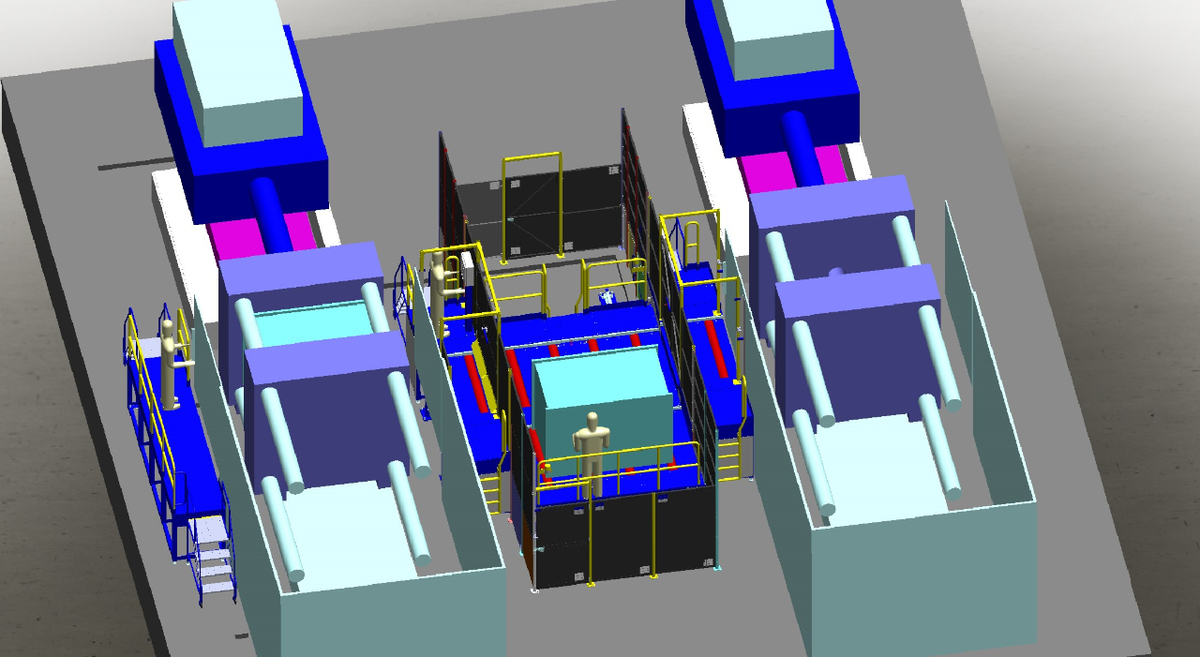

Mechanical designers will review specifications and other data to develop mechanical layouts. Designers have a working knowledge of mechanical parts as well as computer-aided design (CAD) software, such as Solid Works and AutoCAD.

Mechanical designers are able to design complex and simple applications to fit customer’s specifications.

Our designers may travel to job sites or factories to measure physical dimensions for machinery and observe production lines.

Kohan has continually produced many projects and has understood our customer’s needs and expectations. Kohan designers will bring new perspectives and ideas to work with clients to achieve a mutual goal. Kohan will supply an in-depth Service Manual including all layout drawing, spare parts list, and warranty

Review customer application and specifications

Design and prepare of control panel and wiring diagrams(AutoCad Electrical)

PLC Software and Operator Interface design

Programming, testing and site start-up and commissioning

Operating and Maintenance Training

On-call support

PLC Systems and Hardware:

Rockwell/Allen Bradley/Omron/Mitsubishi/Ethernet/IP/EtherCAT, DeviceNet & CC-Link

Effectively install and service our equipment so that our customers get the highest functionality.

Efficient designs and well built equipment can be obstructed if the installation is not accurate. Alignment is key. Experience and proper tools combine to allow alignment tolerances of less than 0.5mm to be achieved.

Kohan service personnel confirm that all interlocks are verified during the installation to ensure that the equipment operates safely and efficiently.

Kohan can provide turn key installations or provide on site technical support to work with customer staff and local contractors. Kohan can prepare re-installation kits and updates to keep our equipment current with local codes and regulations if original equipment needs to be removed and installed elsewhere.

Over the phone and site visits are available to keep the Kohan equipment up and running. Skilled and insightful technicians will help in finding the root causes of equipment difficulties. Communication with the customer is at the center of correcting the current trouble and preventing future incidents.

Extensive supply records, to be able to track all projects.